Introduction to Beams

In the world of structural engineering, beams play a crucial role in supporting loads and distributing stresses throughout a structure. Among the numerous beam types available, two of the most popular are the wf beam vs i beam. Understanding the differences between these two types of beams is vital for selecting the right structural component for construction projects. This article delves deep into the characteristics, applications, design features, performance analyses, cost implications, and best practices for both wide flange (WF) beams and I-beams.

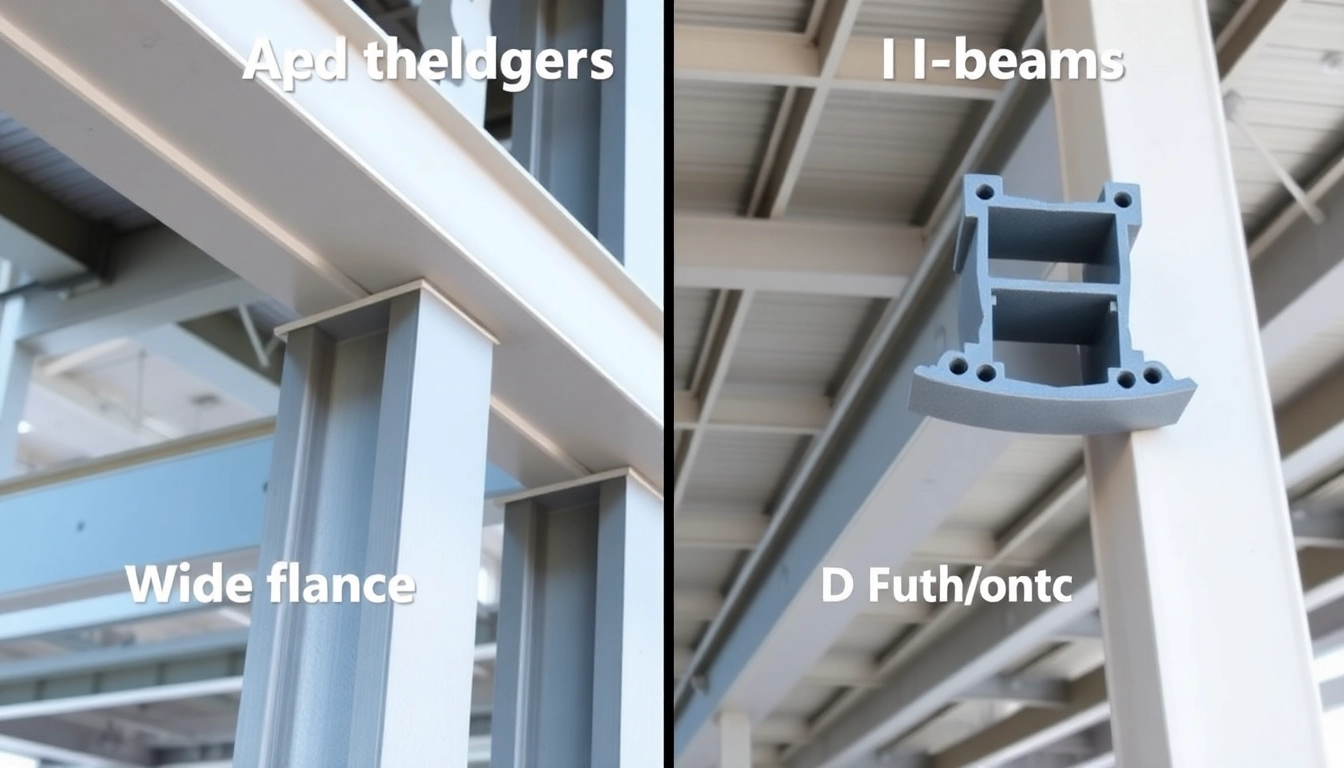

What are WF Beams?

Wide flange beams, often referred to as WF beams, have flanges that are wider and thicker compared to standard I-beams. They are designed in an ‘H’ shape, providing increased strength and stability, which allows them to handle heavier loads. The dimensions of a wide flange beam are often denoted as W followed by the depth of the beam in inches and the weight per foot. This makes identifying and specifying the correct beam easier for engineers and builders.

Widely used in the construction of bridges, buildings, and various structures, WF beams are recognized for their robustness. Their design allows for efficient weight distribution and superior resistance to bending moments, thereby making them suitable for a variety of engineering projects.

What are I Beams?

I-beams, known for their distinctive ‘I’ shape, feature tapered flanges that are significantly narrower than those of wide flange beams. This design results in a lightweight beam that can be manufactured at various depths and thicknesses, catering to specific load-bearing needs. The profile of an I-beam contributes to its ability to withstand force while maintaining relatively low weight.

I-beams are commonly used in structural applications such as floor joists, beams in buildings, and various forms of infrastructure. Although they may not support as heavy a load as wide flange beams, their lighter structure can be beneficial in applications where weight reduction is critical.

Applications in Construction

Both WF and I beams have distinct uses in construction based on their individual strengths. WF beams are favored in scenarios requiring substantial load-bearing capacity, such as in multi-story buildings, bridges, and large commercial structures. Their wide flanges distribute loads more effectively, making them ideal for bearing heavy weights.

Conversely, I beams are often used in applications where space efficiency is essential, such as in roof trusses or areas where a lighter structure is required. They can also be employed in smaller constructions, making them a favorable choice for residential applications.

Design Features of WF vs I Beams

Flange and Web Structure

The structural differences between WF beams and I beams primarily lie in their flange and web configurations. WF beams possess wider and thicker flanges that provide them with enhanced strength and stability. The web of a WF beam is also broader, allowing it to accommodate greater shear forces.

I beams, on the other hand, have a more pronounced taper in their flanges, which reduces their overall weight. This tapering gives the I beam distinct advantages in certain structural applications, allowing for easier handling and installation.

Weight and Load Capacity

One of the key considerations when choosing between WF beams and I beams is their weight and load capacity. WF beams, due to their larger dimensions and denser materials, can handle significantly heavier loads. For instance, a typical WF beam can carry loads up to several thousands of pounds, making them ideal for structural bases of skyscrapers or industrial buildings.

I beams, while lighter, still provide substantial load-bearing capabilities. However, their design limits their weight capacity relative to their size. They are preferred for applications that do not require excessive weight support, such as partition walls and secondary structural supports in buildings.

Material Considerations

Both WF beams and I beams are typically constructed from heavy-duty steel or reinforced materials designed to withstand high stress and environmental conditions. The choice of materials can considerably influence the performance of these beams in terms of longevity and resistance to corrosion.

WF beams are generally made from high-strength steel, enhancing their load-bearing capability. Some manufacturers may offer protective coatings to prevent rusting, particularly in installations exposed to moisture or corrosive elements. I beams, while also made from strong steel, may come in lighter variants, primarily used in less demanding applications.

Performance Analysis

Bending Resistance Comparison

Bending resistance is a critical factor in assessing the structural integrity of beams. WF beams exhibit superior bending resistance due to their wider flanges, which provide larger leverage against bending moments. The additional material in the flanges enables WF beams to absorb more energy and maintain their structural integrity under pressure.

I beams, despite their efficiency and design, have a relatively lower resistance to bending. Their narrower flanges may not distribute loads as effectively as WF beams, leading to a higher propensity for deformation under excessive loads.

Shear Force Distribution

When it comes to handling shear forces, WF beams again demonstrate their advantages. The thicker web and flanges allow these beams to diffuse shear stresses more evenly across their span, minimizing the risk of shear failure. This makes them particularly valuable in high-rise buildings and bridges where shear forces can be substantial.

I beams, while capable of handling shear forces, may require additional support systems such as bracing or reinforcement to manage the stresses they receive effectively. Engineers often take these considerations into account when designing structures that involve load-carrying elements.

Choosing the Right Option

Selecting between WF beams and I beams is contingent upon various project-specific factors, including load requirements, building codes, and budget constraints. A thorough understanding of each beam’s advantages and limitations is essential for making an informed choice.

Consulting with structural engineers about the unique requirements of a project can provide insights into which beam type delivers the best performance for specific applications. Factors such as span length, expected loads, and installation environment will ultimately guide this decision.

Cost Implications

Initial Costs: WF Beam vs I Beam

The initial costs associated with WF and I beams vary significantly based on size, material, and application. Generally, WF beams tend to be more expensive due to their larger dimensions, additional material, and manufacturing complexities. Their cost can be a decisive factor for projects with strict budget requirements.

In contrast, I beams usually represent a more cost-effective option, particularly for projects that do not require maximum load capacities. Their lighter frame allows for simpler handling and installation, potentially reducing labor costs and overall expenditure.

Long-Term Value and Strength

While initial costs provide a straightforward comparison, assessing long-term value is equally essential. WF beams, while more expensive initially, offer increased longevity and strength, which can lead to reduced maintenance costs over the life of the structure. Their ability to withstand greater forces also plays a role in minimizing repair or replacement costs over time.

I beams, although cheaper upfront, may necessitate more reinforcement and maintenance in structures that experience heavy use. Understanding the trade-offs between initial and long-term expenses is crucial for project managers and financial planners in the construction industry.

Project Budgeting Considerations

When budgeting projects, builders should incorporate all aspects related to beam selection into their financial plans. This involves evaluating not just the acquisition costs of beams but also the associated expenses pertaining to support structures, installation, and maintenance. An optimal budgeting approach encourages a holistic view, where the performance and operational efficiencies of either beam type are factored into decision-making.

Engaging with architects and structural engineers early in the budgeting process can clarify costs associated with both WF and I beams. Additionally, planning for potential overruns due to unforeseen structural challenges can protect project finances and timelines.

Conclusion and Recommendations

When to Use WF Beams

WF beams are best utilized in scenarios demanding high load-bearing capacity and resistance to deflection. Structures such as high-rise buildings, large-spanning bridges, and heavy industrial applications typically benefit from the unique properties of wide flange beams. Their ability to distribute weight effectively makes them indispensable in these applications.

When to Use I Beams

I beams are most suitable for lighter constructions where weight efficiency is essential. They are commonly used in residential buildings, smaller commercial projects, and as secondary supports in multi-story structures. Their streamlined form and cost-effectiveness make them advantageous for specific applications, particularly in light-frame constructions.

Future Trends in Beam Design

As the construction industry evolves, both WF and I beams are witnessing advancements in design and materials technology. Innovations aimed at improving strength while minimizing weight are likely to dominate future developments. Enhanced materials, such as high-performance steel and composite materials, may redefine the application scope of both beam types.

Furthermore, sustainability considerations are leading to the development of more environmentally friendly options that maintain the structural efficacy of beams while reducing their carbon footprint. Engineers should remain adept at these emerging trends to ensure they can provide the most advanced solutions for their projects.