Introduction to I Beams and W Beams

When it comes to structural design and construction, choosing the right type of beam is crucial for ensuring the integrity and safety of a building. Two popular shapes used in the construction industry are the I beam and the W beam (wide flange beam). Understanding the differences between these two types of beams can greatly impact project outcomes, as both variations offer unique advantages and applications suited for different engineering requirements. This comprehensive guide will explore the core differences, structural characteristics, and practical considerations for choosing between an i beam vs w beam.

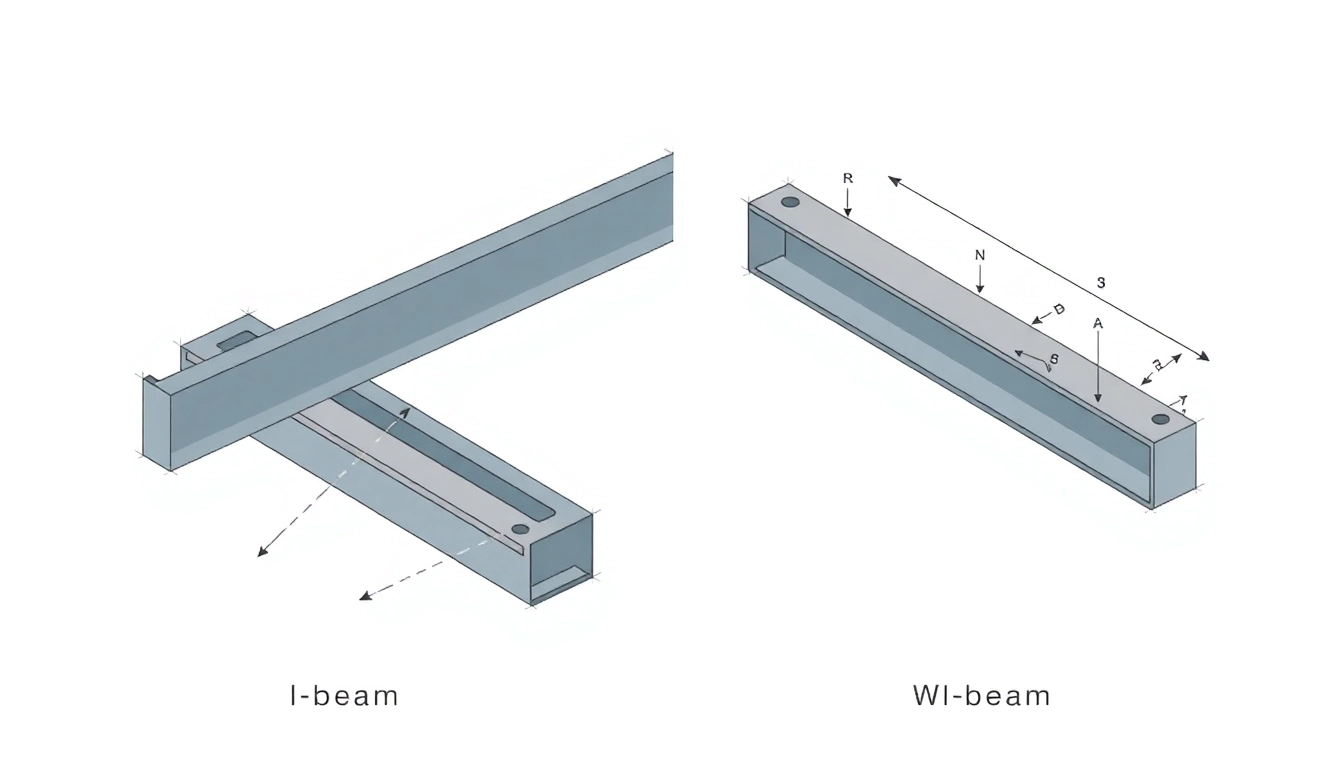

What is an I Beam?

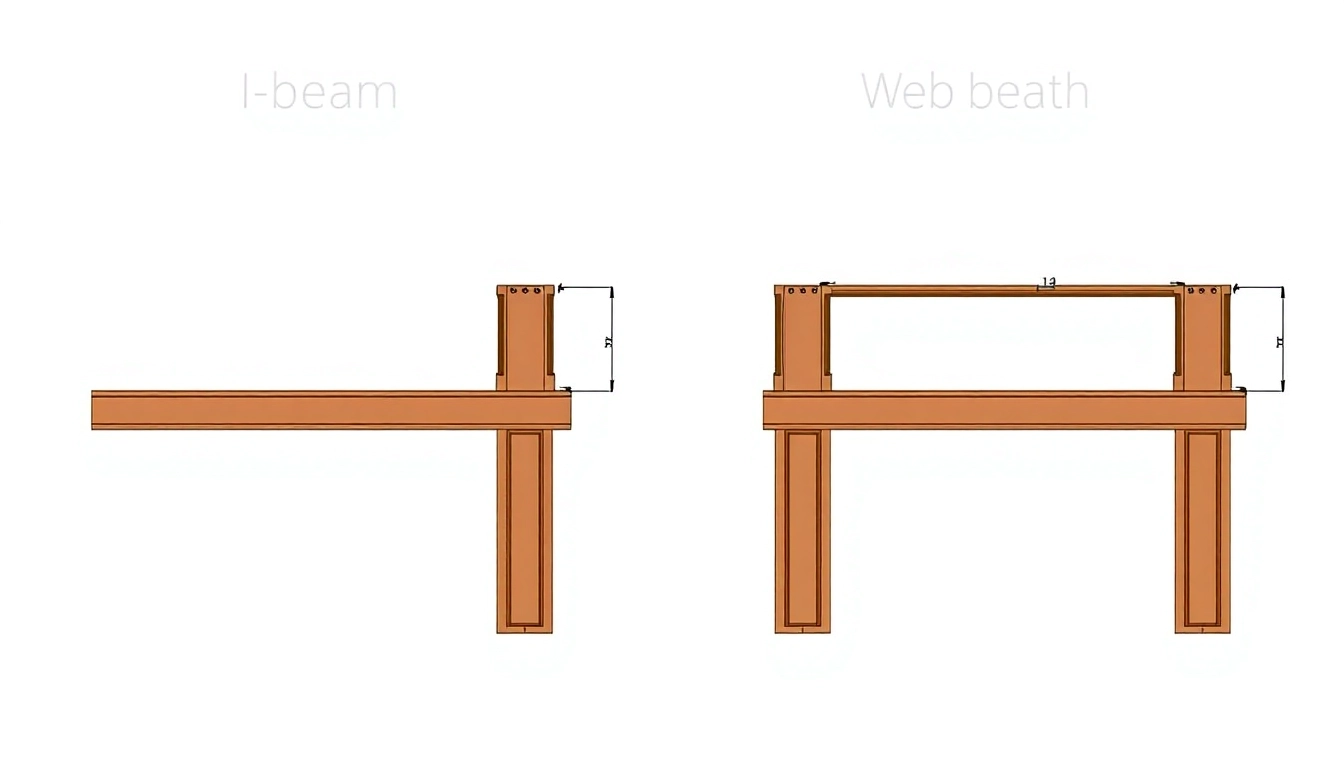

I beams, also known as American Standard Beams (S beams), are designed with a cross-section resembling the capital letter “I.” These beams have two horizontal flanges and a vertical web, with the web being thinner and the flanges often shorter in comparison. The simplicity of the I beam design aids in a number of applications, especially where reductions in weight and material costs are important. They are primarily used vertically as support beams in buildings, bridges, and various other structures. I beams are particularly favored for scenarios where they will experience bending, given their ability to distribute loads effectively.

What is a W Beam?

The W beam, also known as a wide flange beam, has flanges that are wider than those of the I beam and has parallel flanges as opposed to the tapered flanges found on I beams. This design allows W beams to handle a larger amount of weight and stress compared to their I beam counterparts. Their wider flanges make them suitable for a variety of applications, particularly in scenarios where stronger load-bearing capacities are essential. W beams have gained popularity in construction due to their ability to provide overall structural stability with relatively lower material inputs.

Common Applications in Construction

Both I beams and W beams have found their respective applications across various fields in construction. I beams are often utilized in residential construction, including the framing of houses and in commercial buildings, while W beams are predominantly employed in large commercial structures, bridges, and supports that require high load resistance. Understanding the appropriate context for each beam type’s use is essential for achieving optimal structural design.

Structural Characteristics of I Beams vs W Beams

Dimensional Differences Explained

An obvious distinction between I beams and W beams lies in their dimensions. I beams typically have a lesser widespan, with a higher ratio of height to width, which lends itself naturally to bending applications. W beams, by contrast, offer a broader vertical and horizontal surface area due to their wider flanges. This geometry results in a stronger beam housing character traits, making them ideal for load-bearing applications over longer spans without deformation.

Strength and Load-Bearing Capacity

When assessing strength and load-bearing capacity, W beams typically outperform I beams due to their larger cross-section and balanced web-to-flange ratio. A W beam’s greater surface area allows it to distribute stresses more uniformly, making it a preferred choice for heavy construction projects where materials must endure significant loads without compromising safety. I beams, while offering good strength, can serve better in areas where lighter loads are anticipated, making them pragmatic choices in residential applications.

Design and Manufacturing Variations

Both beam types undergo specific design and manufacturing processes that define their characteristics and suitability for various applications. I beams can have rolled or welded flanges, whereas W beams generally feature rolled forms only, providing a smooth surface. Variations in fabrication methods can influence material performance, ultimate strength, and structural integrity, ultimately deciding the best choice for any construction project.

Choosing Between I Beams and W Beams

Project Requirements and Load Considerations

Understanding your project’s requirements is crucial to selecting the appropriate type of beam. Projects expecting heavy loads over large spans would be better served with W beams, whereas projects with lighter loads might benefit from the cost savings and efficiency of I beams. Conducting a thorough analysis of projected loads, possible dynamic effects, and material costs will help determine the most suitable option for each application.

Cost Analysis and Material Efficiency

Cost considerations can play a significant role in material selection. Generally, I beams are less expensive than W beams due to lesser material requirements. Cost-effective solutions for smaller structural applications can be achieved with I beams. However, for larger construction projects, W beams’ superior performance in load-bearing applications can justify the larger investment. It’s important to balance cost with long-term sustainability goals by considering the material waste, delivery, and labor resources as well.

Durability and Maintenance Factors

Durability is a key factor in determining the lifespan of structural elements. Both I beams and W beams can exhibit high levels of strength when constructed from quality materials. However, W beams generally possess a slight edge due to their distributed load capacity, allowing for longer spans with fewer support columns. Regular inspections and maintenance routines should be established to address potential issues in either beam type’s longevity.

Installation and Implementation Techniques

Safe Installation Practices

Proper installation of both I and W beams is vital for structural safety. Employing experienced personnel and utilizing appropriate equipment can prevent risks associated with improper handling. Beam positioning and securing needs to meticulously follow engineering specifications. Safety measures include the use of personal protective equipment and the establishment of clear communication protocols during the installation process.

Common Challenges During Implementation

Common challenges might arise during the implementation of both I and W beams including misalignment, inadequate load assessments, and unexpected environmental influences. Anticipating these issues through thorough project planning and on-site inspections can mitigate potential problems before installation begins. Moreover, having contingency plans and responsive strategies will further enhance project’s success.

Best Practices for Structural Integrity

Ensuring structural integrity throughout the lifecycle of both beam types requires adherence to best practices including proper design and load assessments, consistent quality control during manufacturing, and stringent installation protocols. Regular inspections post-implementation, along with carefully scheduled maintenance, will preserve the characteristics and capacities of the beams and ensure safety standards are met across all structures.

Future Trends in Beam Design

Innovations in Structural Engineering Materials

The future of beam design focuses on innovations in materials and manufacturing techniques. Emerging composite materials and high-strength steel are paving the way for lighter, yet more durable, beams that can minimize costs while enhancing structural integrity. Advanced engineering technologies may also enable smarter design options that can adapt to varying loads and stresses, thereby pushing the boundaries of traditional beam applications.

Sustainable Practices in Beam Usage

As the construction industry pushes towards greener practices, the integration of sustainable materials into beam construction will likely gain momentum. Enhanced recycling of existing materials, alongside innovations in eco-friendly manufacturing processes, can progressively decrease the environmental footprint associated with structural beams. Adopting these practices can unravel a new era for the industry, reflecting growing concerns surrounding sustainability.

The Evolving Standards of Building Codes

Regulatory changes in building codes can influence the design and usage of I and W beams. With growing emphasis on safety and sustainability considerations, construction professionals are advised to stay abreast of evolving standards that affect beam specifications. Emphasizing compliance while implementing new technologies and procedures will lead to structural systems that adhere not only to current best practices but also anticipate future demands.