Understanding MC3 and MC4 Connectors

Solar energy has become a dominant player in the renewable energy market, and connectors play a vital role in ensuring that solar panels operate efficiently. Among the most widely used connectors in solar systems are MC3 and MC4 connectors. Understanding the differences between mc3 vs mc4 can significantly impact installation practices, safety, and system performance. In this article, we will explore the features, specifications, and advantages of these connectors, equipping solar installers and enthusiasts with the knowledge they need to make informed decisions.

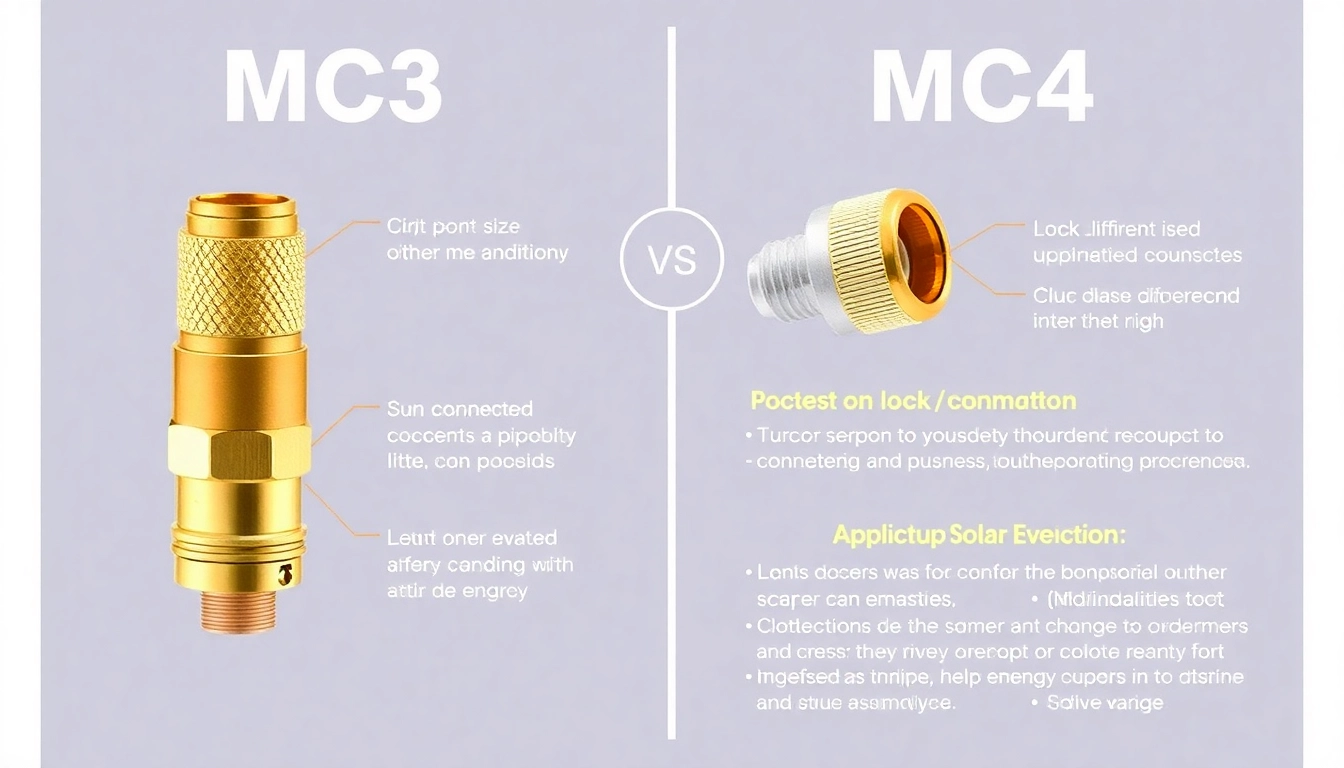

What are MC3 Connectors?

MC3 connectors, produced primarily for solar panel applications, are single-contact electrical connectors designed to maintain a secure connection between solar panels and other system components. They are characterized by a pin diameter of 3 mm, which was considered standard in earlier installations. MC3 connectors are renowned for their durability and ease of use; however, as the solar industry has evolved, these connectors have increasingly been phased out in favor of more advanced options.

Due to their design, MC3 connectors are typically rated at voltages of up to 600 volts and can handle a maximum of 30 amps of current. MC3 connectors provide an ingress protection rating of IP65, indicating that they are reasonably resistant to dust and can withstand water splashes from any direction. Yet, this rating falls short of the enhanced protection offered by more recent connector designs.

What are MC4 Connectors?

MC4 connectors are the advanced successor to MC3 connectors, featuring a pin diameter of 4 mm. This slight increase enhances the connectivity and reduces the resistance typically experienced in solar systems. MC4 connectors are designed to interlock and are essential for ensuring a robust connection, effectively reducing the risk of disconnection caused by mechanical vibration or thermal expansion.

Characterized by a more sophisticated locking mechanism, the MC4 connectors also feature an IP67 ingress protection rating, making them waterproof and suitable for outdoor applications. They can handle higher current loads, typically rated at 40 amps at up to 1000 volts, which greatly expands their usability in modern solar installations. This makes MC4 connectors not only more reliable but also far superior in terms of safety and performance.

Common Applications of MC3 and MC4 Connectors

Both MC3 and MC4 connectors find extensive application in the solar energy sector, connecting solar panels to inverters, charge controllers, and battery systems. MC3 connectors were commonly used in older solar panel models, while MC4 connectors are now the industry standard for newer systems. The transition from MC3 to MC4 has been driven by the need for more secure, efficient, and safer connections in solar installations, especially in residential and commercial setups. Due to the higher voltage and current ratings of MC4 connectors, they allow for the use of thinner wiring to achieve longer distances between components, which can facilitate larger installations.

Key Differences Between MC3 vs MC4

Design Features Comparison

When comparing MC3 and MC4 connectors, the most significant design differences lie in their sizes and locking mechanisms. MC3 connectors are smaller with a pin diameter of 3 mm, while MC4 connectors measure 4 mm. The increased diameter of the MC4 connectors facilitates a better electrical connection and minimizes resistance.

The locking mechanisms of the two connectors also vary. MC3 connectors typically utilize a simple friction fitting, which relies on the pin’s fit to secure the connection. In contrast, MC4 connectors employ a more advanced locking system that secures the connection with a positive latch, further reducing the risk of accidental disconnections caused by environmental factors.

Electrical Specifications

Examining the electrical specifications of MC3 and MC4 connectors reveals essential information for choosing the right connector for specific applications. MC3 connectors usually operate at a maximum of 600 volts and 30 amps. However, the MC4 connectors comfortably function at voltages up to 1000 volts and can handle 40 amps of current. This capability not only improves performance but also enhances the safety of high-voltage installations.

Furthermore, the higher rating of MC4 connectors allows for better adaptability in larger solar installations, catering to arrays that experience higher amperages and voltages, which helps optimize their overall performance in terms of energy production.

Locking Mechanisms: Securing Connections

The locking mechanism in MC4 connectors provides a significant advantage over MC3 connectors. MC4 connectors utilize a positive-locking feature that ensures a tighter and more reliable connection. This locking system creates a more stable connection that can withstand mechanical vibrations and temperature fluctuations without loosening or disconnecting, making it particularly valuable in outdoor environments.

Having a secure connection is vital for protecting against system failures. The enhanced locking capabilities of MC4 connectors contribute to better performance and safety in solar applications, reducing risks associated with accidental disconnections and mitigating potential damage caused by environmental factors.

Advantages of MC4 Over MC3

Improved Safety Features

Safety is a paramount concern when dealing with electrical systems, especially those operating at high voltages like solar arrays. MC4 connectors are designed with several safety features that are either non-existent or inferior in MC3 connectors. Among these features is the IP67 rating, which guarantees that connectors are dust-tight and can withstand water immersion at depths up to one meter for about 30 minutes.

Additionally, the robust locking mechanism in MC4 connectors significantly reduces the likelihood of disconnections during operation, thereby enhancing the overall safety of the solar system. As such, switching to MC4 connectors not only improves performance but also elevates safety standards in solar installations.

Better Performance in Various Conditions

MC4 connectors are explicitly designed to perform optimally in various environmental conditions. Their robust construction and superior ingress ratings mean they can withstand harsh weather, including heavy rain, high winds, and extreme temperatures. This resilience translates to longevity, reducing the frequency of maintenance and replacements. Moreover, the efficiency benefits of lower resistance in MC4 connectors can contribute to increased energy output from solar panels, securing better returns on investments over time.

Many solar installers report improved system performance and reduced downtime associated with weather-related issues when utilizing MC4 connectors. This responsiveness to climate conditions has made them the preferred choice in both residential and commercial settings.

Industry Standard Adoption

The transition from MC3 to MC4 connectors is evident in the solar industry, as MC4 has become the recognized standard for solar panel connections. Newer solar panel models almost exclusively feature MC4-compatible connections, making it increasingly challenging to find MC3 components for new installations.

Furthermore, as regulatory requirements have evolved, certification bodies are now favoring MC4 connectors due to their enhanced safety and operational standards. The universal adoption of MC4 connectors has paved the way for simpler installation processes, compatibility, and maintenance, solidifying their status as the go-to connector in modern solar energy systems.

How to Choose Between MC3 and MC4

Evaluating Your Solar Needs

Determining whether to use MC3 or MC4 connectors largely depends on your specific solar needs and project requirements. If you are working with older solar panels or existing installations that still utilize MC3 connectors, it may be practical to continue using them until a complete system redesign or upgrade is warranted. However, for new installations or upgrades, MC4 connectors are recommended due to their superior performance and safety standards.

Consulting with a qualified solar installer can also help assess the suitability of MC4 connectors for your specific setup, considering factors like energy output expectations, budgetary constraints, and installation requirements.

Compatibility with Solar Panels

Compatibility with the solar panels you intend to use is another vital consideration. Many contemporary solar panels are designed with MC4 connectors as their standard connection type. Therefore, using MC4 connectors ensures that you create an optimal and efficient connection with your solar panels, maximizing energy transfer and minimizing losses.

It’s also worth noting that if future upgrades to your solar system are likely, choosing MC4 connectors now can help avoid potential compatibility issues down the line, allowing for easier integration with advanced photovoltaic technology.

Cost Considerations

Cost is always a critical factor in any project. In general, MC3 connectors have been less expensive than their MC4 counterparts due to their phase-out status. However, the long-term advantages of investing in MC4 connectors can outweigh the initial cost. The enhancements in performance, safety, and durability imply that over time, you will experience less maintenance, fewer replacements, and ultimately a higher energy yield from your solar energy system.

Funding incentives and reimbursement programs for solar installations in many regions may also factor into your overall budget considerations, guiding you toward selecting the right connectors that align with those goals.

Future of Solar Connectors: MC3 vs MC4

Industry Trends and Changes

As the solar industry continues to evolve, trends indicate a move toward technologies that incorporate higher efficiencies and improved safety features. The transition to MC4 connectors represents a shift into a new era of connector technology tailored for high-performance solar systems. Innovations in materials and manufacturing will continue to shape connector capabilities, enhancing user experience and installation processes.

The rapid increase in solar energy adoption globally underscores the significance of reliable connectors like MC4, which are crucial for supporting increasing system sizes and demands.

Transitioning from MC3 to MC4

For those who currently have systems utilizing MC3 connectors, it’s worth exploring transitioning to MC4 when feasible. Transitioning may involve retrofitting existing systems or replacing connectors during upgrades. This move can provide considerable benefits, including reducing the risk of future compatibility issues and ensuring that your solar system meets emerging safety standards.

Careful planning is crucial during this transition to avoid system downtime and facilitate smooth connections, especially in larger setups where multiple panels are involved.

Innovation in Connector Technology

The future of solar connectors extends beyond mere compatibility and standardization. Ongoing research and development in connector technology aim to produce even more efficient, safer, and user-friendly designs that cater to the evolving energy landscape. Innovations such as intelligent connectors with monitoring capabilities or IoT integration may soon enter the market, providing real-time analysis and metrics that improve system performance and maintenance.

In summary, both MC3 and MC4 connectors play essential roles in solar energy systems, but the shift toward MC4 technology highlights the need for progress in safety, efficiency, and performance in the ever-growing renewable energy market.