Understanding I-Beams and W-Beams

When it comes to structural engineering and construction, choosing the right type of steel beam is crucial for the durability and stability of a project. Among the most commonly used types are the I-beam and the W-beam (wide flange beam). Understanding the differences between these two beam types can greatly impact the design and functionality of engineering structures. In this article, we will dissect the characteristics of each beam, comparing them in terms of design, performance, and application. This comprehensive guide provides insight into the i-beam vs w beam debate, equipping you with the knowledge needed to make informed decisions.

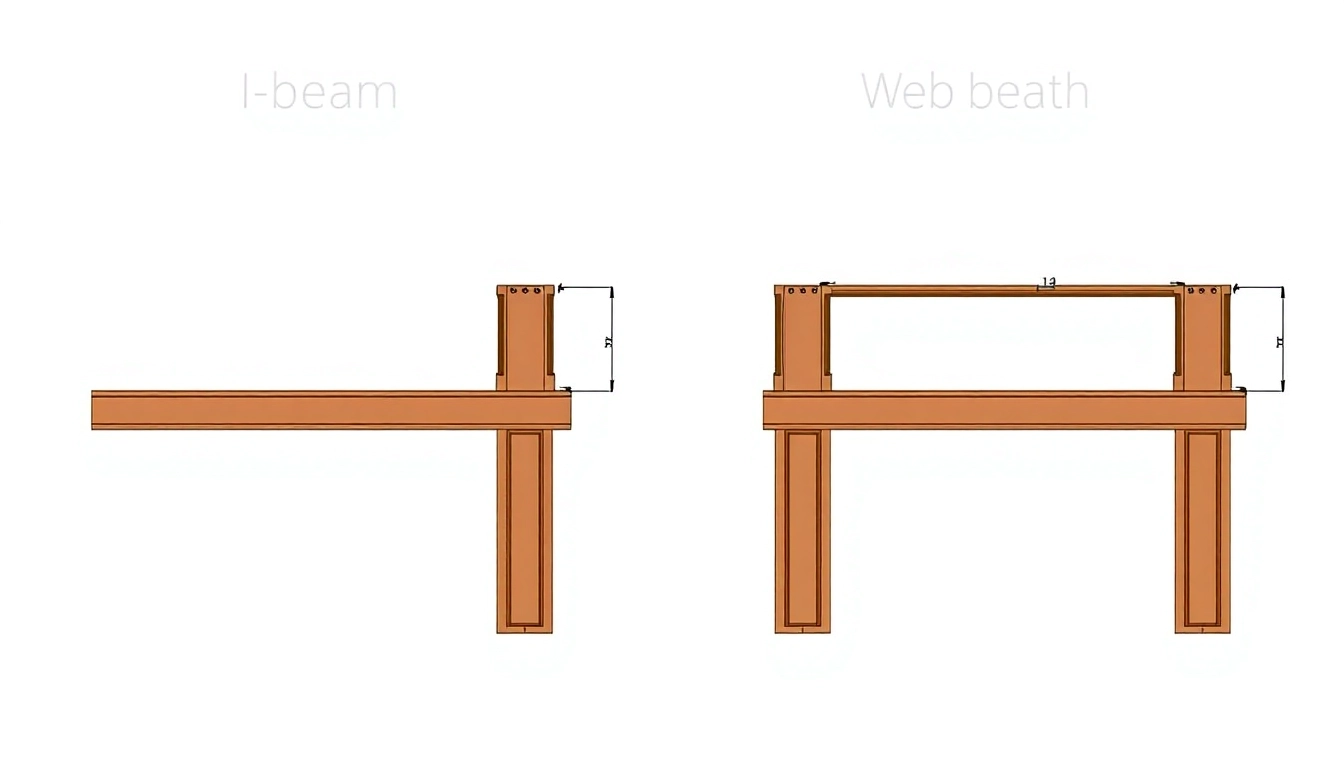

What is an I-Beam?

An I-beam, sometimes referred to as a universal beam or H-beam, derives its name from its distinctive cross-section that resembles the letter ‘I’. Typically made from structural steel, I-beams are characterized by two horizontal flanges (top and bottom) connected by a vertical web. I-beams are used extensively in construction due to their ability to handle substantial loads and provide structural support. The tapered flanges of an I-beam are narrower than those of a W-beam, which allows for a reduced material weight, making them a cost-effective option in some applications.

What is a W-Beam?

A W-beam, or wide flange beam, features wider flanges compared to the I-beam. This beam type also has a similar cross-section to the letter ‘H’, which allows it to support greater loads due to its increased surface area. The web of a W-beam is generally thicker than that of an I-beam, providing better torsional resistance and making it suitable for applications that require robust structural integrity. W-beams come in a variety of sizes and lengths, affording engineers and builders flexibility in design and application.

I-Beam vs W Beam: Structural Design Explained

The design of both beam types plays a pivotal role in their applications. I-beams are typically used where lighter loads are involved, while W-beams are preferred in heavy-load scenarios due to their enhanced load-bearing capacity.

Key Differences in Design

Flange and Web Dimensions

The differences in the flange and web dimensions are fundamental to understanding the strengths and weaknesses of each beam type. I-beams feature a narrower flange and web, which can facilitate the use of less material in situations where weight savings are critical. In contrast, W-beams, with their wider flanges, provide more surface area for load distribution. This design aspect contributes to their popularity in heavy construction projects.

Weight and Material Considerations

Weight is an important factor when selecting between I-beams and W-beams. Due to their streamlined design, I-beams are typically lighter, making them easier to handle and install. Consequently, they are often the preferred choice in lighter structural frameworks. However, W-beams, although heavier, compensate for this with their enhanced durability and superior load capacity, making them ideal for more demanding applications.

Applications Based on Design Types

Applications vary widely based on the design of the beam. I-beams are frequently utilized in the construction of bridges and buildings, as well as in roofs and floors where vertical loads are moderate. On the other hand, W-beams are specifically designed for heavy-duty applications, such as high-rise buildings, parking garages, and industrial facilities, where significant load-bearing capacity is essential.

Performance Metrics

Load-Bearing Capacity

The load-bearing capacity is perhaps the most critical performance metric when selecting between I-beams and W-beams. I-beams typically excel in applications requiring linear load distribution, while W-beams provide superior performance under transverse loading due to their broader flanges. Engineering calculations are essential for determining the optimal beam type for any specific application, ensuring that load capacity is adequately addressed.

Torsional Resistance Comparison

Torsional resistance refers to the ability of a beam to withstand twisting forces. In this regard, W-beams have a significant advantage due to their design, which offers greater resistance against twisting and bending. Projects involving complex designs or requiring materials to endure high torsional loads will greatly benefit from the robustness of W-beams.

Durability Insights

Durability is another crucial factor for consideration. I-beams are effective in moderate environments but may require additional treatment for corrosion resistance, especially in harsh conditions. Conversely, W-beams, with their thicker web and flanges, offer enhanced durability and are often manufactured from high-strength steel, which elevates their resistance to the elements and overall longevity.

Common Applications and Industries

Construction Uses of I-Beams

In construction, I-beams are widely employed in residential and commercial buildings. They are often integrated into the frameworks of buildings as support beams, floor joists, and roof trusses. Their lightweight nature allows for efficient transport and installation, which can lead to reduced labor costs and construction time.

W-Beam Applications in Engineering

W-beams shine in scenarios demanding high strength and robustness. They are commonly used in heavy industrial applications, such as the construction of bridges, large commercial buildings, and wind turbine towers. Their design makes them suitable for high-load scenarios, ensuring the integrity and stability of the structures they support.

Industry-Specific Recommendations

Each type of beam accommodates specific industry needs. In the automotive industry, for example, I-beams may be selected for lightweight vehicle frames, while W-beams serve well in the construction of loading docks and heavy machinery foundations, where strength and stability are paramount.

Conclusion: Choosing Between I-Beams and W-Beams

Factors to Consider in Your Project

Choosing between I-beams and W-beams ultimately depends on various factors, including load requirements, project weight constraints, and environmental conditions. Factors like design complexity, installation processes, and future maintenance must also be taken into account. Engineers and architects must assess these parameters carefully during the planning phase to ensure the selected beam type meets the project’s demands effectively.

Future Trends in Beam Engineering

The future of beam engineering is likely to witness advancements in materials and design technologies. Innovations such as high-strength alloys and composite materials could enhance the performance of both I-beams and W-beams, enabling lighter, stronger, and more environmentally friendly construction solutions. Continued research into the optimization of beam designs will also contribute to improving load capacities and enhancing torsional resistances.

Resources for Further Information

As with any engineering choice, it is essential to stay informed. Consulting structural engineering handbooks, attending industry conferences, and participating in webinars can provide valuable insights into advancements and best practices related to I-beams and W-beams. Engaging with professionals in the field and accessing comprehensive resources will equip you with the knowledge needed to make informed choices in future projects.