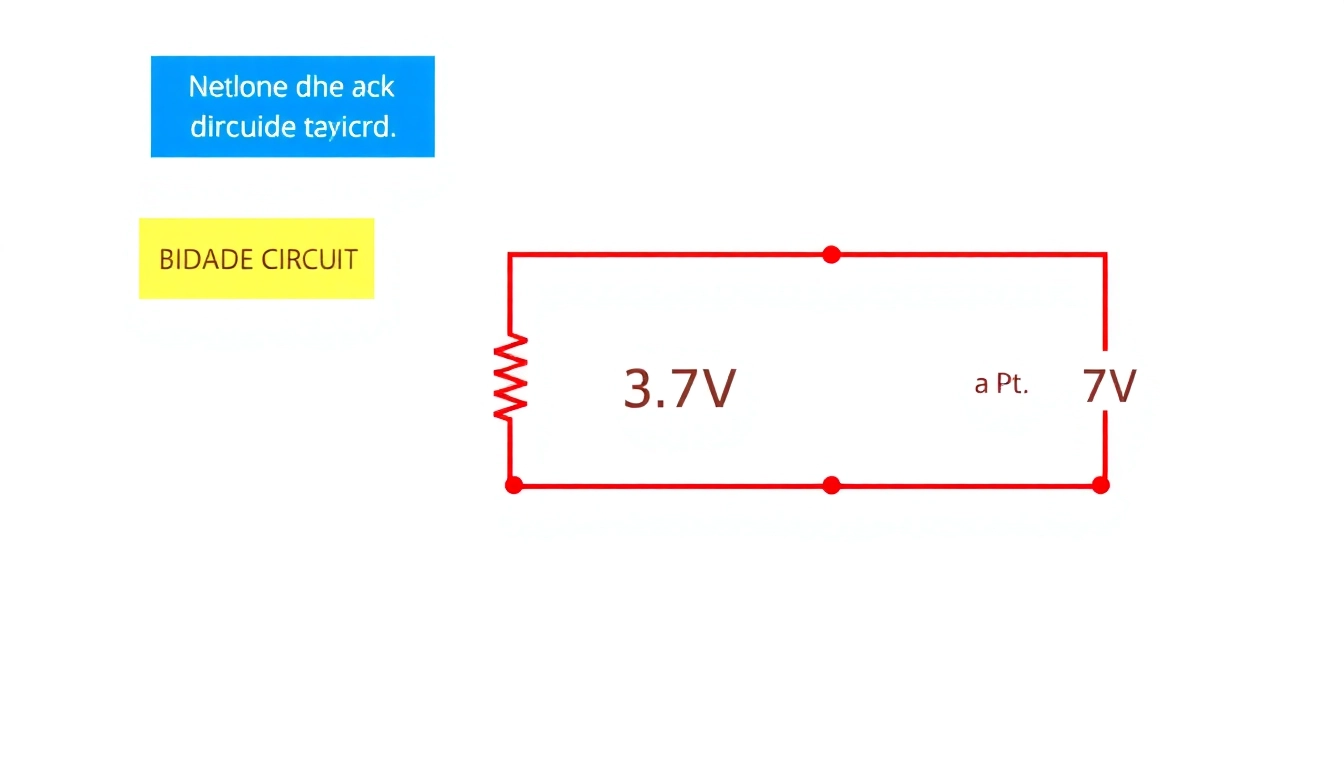

1. What is Diode Voltage Drop?

1.1 Definition of Diode Voltage Drop

The term diode voltage drop refers to the electrical potential difference across a diode when it conducts current. Specifically, this is known as the forward voltage, which is the voltage necessary to make a diode conduct when it is forward-biased. When a voltage is applied across a diode, a certain threshold must be surpassed for the diode to enter its conducting state. Exceeding this threshold leads to a gradual increase in current flow.

1.2 Importance in Electronics

The diode voltage drop plays a crucial role in electronic circuits, particularly in determining the effective voltage in various applications. Understanding the voltage drop is essential for accurate circuit design, helping engineers ensure that devices operate within their rated power limits. This knowledge aids in selecting appropriate components and in preventing damage due to excessive voltage or unintended current paths.

1.3 Common Types of Diodes and Their Drops

Different types of diodes exhibit different voltage drops. The most common type, the silicon diode, has a forward voltage drop of approximately 0.7 volts. However, other types of diodes offer varied characteristics:

- Germanium Diodes: These typically have a lower forward voltage drop, around 0.3 volts, making them suitable for low-voltage applications but less stable than their silicon counterparts.

- Schottky Diodes: Known for their low forward voltage drop, usually between 0.2 to 0.4 volts, Schottky diodes are favored for fast-switching applications due to their rapid response time.

- Zener Diodes: Designed to operate in reverse bias, Zener diodes maintain a stable voltage drop (Zener voltage) across their terminals when reverse-biased, which is crucial for voltage regulation.

2. Factors Affecting Diode Voltage Drop

2.1 Current and Its Influence

The forward voltage drop across a diode is not constant; it varies with the amount of current flowing through the diode. According to the Shockley diode equation, the relationship between the current and voltage drop is exponential, meaning as the current increases, the voltage drop also increases but at a decreasing rate after a certain point.

This phenomenon is often represented in their I-V characteristics, where you can see the curve becoming steep after the threshold voltage is achieved, indicating rapid increases in current yield increasingly small voltage increases.

2.2 Temperature Effects

Temperature is another critical factor that influences diode voltage drop. As the temperature increases, the forward voltage drop tends to decrease. This decrease occurs due to increased carrier concentration in the semiconductor material, which allows more current to flow at lower voltages. Typically, the voltage drop reduces by about 2 mV for every degree Celsius rise in temperature. This temperature dependency emphasizes the need for thermal management in circuits using diodes, especially in high-power applications.

2.3 Material Composition Variations

The material used for constructing the diode significantly impacts its voltage drop characteristics. Silicon and germanium are the most common semiconductor materials; however, advancements have led to other options like Gallium Arsenide (GaAs) and Silicon Carbide (SiC). Each material has unique electric properties, leading to variations in conduction and voltage tolerance:

- Silicon: As previously mentioned, silicon diodes typically have a voltage drop of 0.7V.

- Germanium: These diodes, with their low voltage drop, are often preferred in low-power applications but suffer from higher leakage currents.

- SiC and GaAs: These newer materials offer advantages like high-temperature resistance and higher voltage ratings, making them excellent candidates for specialized applications.

3. Calculating Diode Voltage Drop

3.1 Using the Shockley Equation

The Shockley diode equation provides a quantitative basis for calculating the current through a diode given the voltage across it:

I = Is * (e^(V/(nVT)) – 1)

Where:

- I: Current through the diode

- Is: Reverse saturation current

- V: Voltage across the diode

- n: Ideality factor (typically between 1 and 2)

- VT: Thermal voltage (~25mV at room temperature)

This equation is primarily useful in understanding the non-linear nature of diode behavior, allowing engineers to predict operational characteristics under varying current levels.

3.2 Practical Calculation Examples

Let’s consider a silicon diode with a reverse saturation current (Is) of 10nA. Suppose the forward voltage (V) is set at 0.7V. Plugging these values into the Shockley equation can help predict the current through the diode:

I = 10nA * (e^(0.7V/(0.025V)) – 1)

Solving this would give the exact current, showcasing how the voltage directly affects the function of the diode.

3.3 Voltage Drop Calibration Techniques

For practical applications, correctly calibrating the voltage drop across diodes may involve several steps:

- Setting Up Experimental Conditions: Ensure stable temperature and current levels during testing to obtain reliable readings.

- Using Multimeters: Employ precision multimeters to measure voltage drop while gradually increasing current to observe the change in response.

- Comparison with Specifications: Validate measured drops against manufacturer specifications for specific diode models.

4. Applications of Diode Voltage Drop

4.1 Power Supply Circuits

In power supply applications, diodes help in voltage regulation, rectification, and protection. When used in rectifier circuits, the forward voltage drop must be considered to ensure the output voltage remains within acceptable limits. Engineers often employ multiple diodes in series to achieve desired voltage drops for specific applications.

4.2 Signal Processing

Diodes are commonly used in signal processing, particularly in demodulation and signal clipping. The voltage drop characteristic enables them to perform effectively in removing unwanted noise or shaping analog signals according to set thresholds. Understanding the voltage drop associated with various diodes can guide designers in selecting the optimal isolation components for a circuit for desired performance.

4.3 Safety and Protection Circuits

Diodes play a critical role in protecting circuits from reverse polarity or excessive voltage conditions. For example, Zener diodes are widely utilized in clamping circuits to maintain voltage levels. By leveraging their voltage drop capabilities, engineers can ensure system safety and longevity by effectively controlling the voltage within operational limits.

5. Troubleshooting Diode Voltage Drop Issues

5.1 Common Problems and Solutions

There are several issues concerning diode voltage drops, including excessive drop, diminished conduction capabilities, or even complete failure. Some common problems and solutions include:

- Problem: Voltage drop exceeds typical range (e.g., >0.8V for silicon diode). Solution: Check for excessive current flow or a faulty diode.

- Problem: Diode not conducting. Solution: Verify appropriate biasing and ensure the voltage applied exceeds the diode’s forward voltage requirement.

- Problem: Inconsistent voltage drop (possibly due to heating). Solution: Implement adequate cooling techniques to maintain a stable operating temperature.

5.2 Testing Diodes in Circuits

Testing diodes in an operational circuit requires specific tools and methodologies to assess their performance. Common methods include:

- Using a Multimeter: Measure the forward and reverse bias voltage to assess functionality.

- Temperature Monitoring: Conduct tests while monitoring the diode’s temperature to detect changes that may affect performance.

- Simulating Circuit Conditions: Use circuit simulation software to predict expected voltage drops under theoretical conditions.

5.3 When to Replace a Diode

Replacement of diodes should be considered when they exhibit consistent failure signs such as:

- High Leakage Current: This indicates degradation of the diode’s internal structure.

- Physical Damage: Any noticeable damage to lead or packaging can render a diode non-functional.

- Excessive Heat or Burning Smell: This often signifies an internal failure, indicating a need for immediate replacement to prevent circuit damage.